Fiberglass is one of the most common materials used in boat construction, but not all fiberglass is created equal. This guide explores the different types of fiberglass, the resins used, and how construction methods can affect durability, strength, and cost. Additionally, we’ll provide helpful links to other important aspects of boating to enhance your knowledge and preparation.

What is Fiberglass?

Fiberglass is a composite material made from glass fibers reinforced with plastic. The plastic, or resin, acts as a binder, holding the fibers together. Fiberglass is lightweight, durable, and can be shaped into various forms, making it a popular choice for boat hulls. It offers high tensile strength and compressive strength, key characteristics for vessels designed to withstand the pressures of marine environments.

For an in-depth understanding of boat materials and how to maintain them, you might want to check out this guide on preparing and maintaining the freeboard.

Types of Fibers in Fiberglass Mats

Fiberglass mats can be made from various fibers:

- Glass Fibers: The most common type, offering strong tensile properties.

- Carbon Fiber: Lighter and stronger than glass, but significantly more expensive. Used primarily in high-performance racing boats and masts.

- Natural Fibers (Rare): Such as wood or paper fibers, occasionally used but less durable and not widely adopted.

Types of Fiberglass Mats

The type of mat used affects the strength and flexibility of the fiberglass:

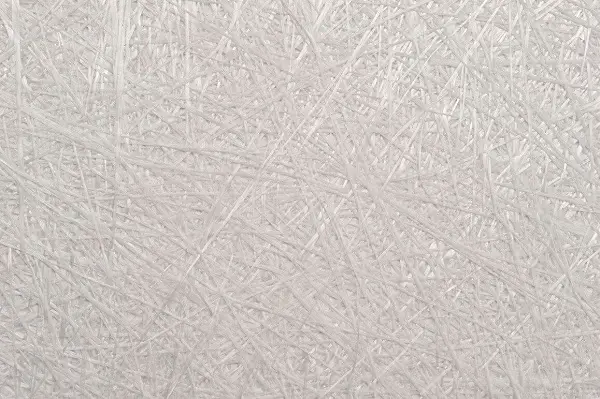

- Chopped Strand Mat (CSM): The most common and affordable option. The fibers are randomly arranged, making it easy to work with but weaker compared to woven mats.

- Woven Fiberglass Cloth: Provides greater strength and durability. These mats are used in higher-end applications but are more difficult to work with.

- Biaxial, Triaxial, and Quadraxial Mats: Offer strength in multiple directions, ideal for areas that experience stress from various angles.

- Carbon Fiber Mat: Strongest but most expensive, typically used in performance vessels.Key Data:

- CSM Strength: 150-300 MPa (tensile strength)

- Woven Fiberglass: Up to 400 MPa

- Carbon Fiber: 500-700 MPa

Types of Resins in Fiberglass

Fiberglass boats use different types of resins as a binder:

- Polyester Resin: The most commonly used resin, known for its affordability. However, it is more prone to osmosis, which can lead to blistering in the hull.

- Epoxy Resin: Stronger and more durable than polyester resin, epoxy is resistant to osmosis but is more expensive and harder to work with.

Resin Comparison:

| Resin Type | Cost | Strength | Durability | Resistance to Osmosis |

|---|---|---|---|---|

| Polyester Resin | Low | Moderate | Moderate | Low |

| Epoxy Resin | High | High | High | High |

Repairing Fiberglass

When repairing fiberglass, it’s critical to use the right type of resin. You cannot apply polyester resin over epoxy, as it won’t adhere properly. Always use epoxy resin for repairs if you’re unsure about the original resin used. Here’s a simple guideline:

- Polyester Repairs: Only on polyester-based fiberglass.

- Epoxy Repairs: Can be applied to both epoxy and polyester-based fiberglass.

Methods of Fiberglass Construction

Fiberglass boats are built using different techniques, each affecting the final strength and durability:

- Hand-Laminated Fiberglass: A manual method where layers of fiberglass are placed in a mold, and resin is applied by hand. It’s cost-effective but susceptible to errors like moisture contamination.

- Vacuum-Infused Fiberglass: In this method, resin is pulled into the mold under vacuum pressure, eliminating the risk of air bubbles and moisture, resulting in a more durable construction.

- Injection Molded Fiberglass: Used for small vessels like kayaks. Fibers are injected into a mold, which results in less strength than hand-laid or vacuum-infused fiberglass.

If you’re interested in expanding your knowledge on different boat types, this guide on buying a sailboat provides helpful insights.

Sandwich Construction in Boats

A sandwich construction uses layers of fiberglass with a core material in between, creating a stronger, more rigid structure without significantly increasing weight. Common core materials include:

- Divinycell (PET): A strong, lightweight foam with excellent fire resistance and durability. It’s also environmentally friendly as it can be recycled.

- Balsa Wood: While cheap and light, balsa wood is prone to rot if moisture seeps in, compromising the hull’s strength.

Core Material Comparison:

| Material | Strength | Weight | Durability | Resistance to Rot |

|---|---|---|---|---|

| Divinycell | High | Low | High | High |

| Balsa Wood | Moderate | Very Low | Low | Very Low |

Safety Concerns with Balsa Wood

Boats with balsa wood cores are more susceptible to rot, especially in humid environments. If moisture penetrates the hull, it can cause the wood to break down, creating soft spots and weakening the structure. You can detect moisture issues by:

- Sound Test: Tapping the hull with a hammer. A dull sound indicates moisture.

- Moisture Meter: Use to detect water within the hull layers.

Should You Buy a Fiberglass Boat?

When choosing a fiberglass boat, consider your budget, the materials used, and the intended use. High-performance boats may require carbon fiber mats and epoxy resin, while a more affordable boat for leisurely cruising might use CSM and polyester resin. It’s worth noting that many boats with chopped strand mat and balsa wood cores have sailed around the world successfully, but these cheaper materials may require more maintenance over time.

Key Takeaways

- Fiberglass can be made from various fibers, mats, and resins, each with strengths and weaknesses.

- Epoxy resin is stronger but more expensive, while polyester resin is more affordable but prone to osmosis.

- Balsa wood in sandwich construction can rot if not properly maintained.

- Boats built with vacuum infusion are generally stronger than hand-laminated or injection-molded ones.